Features of HSNF-1

1.E+H Electromagnetic flow-meter and modes of weighting for your choose.

2.Siemens PLC control man-machine interface monitoring operation.

3.Completion of production process in automatic mode with the features of high automation extent& convenience for operation.

4.High hygiene level by CIP automatic cleaning system.

5.The whole equipment is made of stainless steel SUS304, all the surface contacting products are manufactured in stainless steel 316L , other components , such as Rubber, glass, .....are made in sanitary materials approved in food industrial applications , all materials are FDA approved.

|

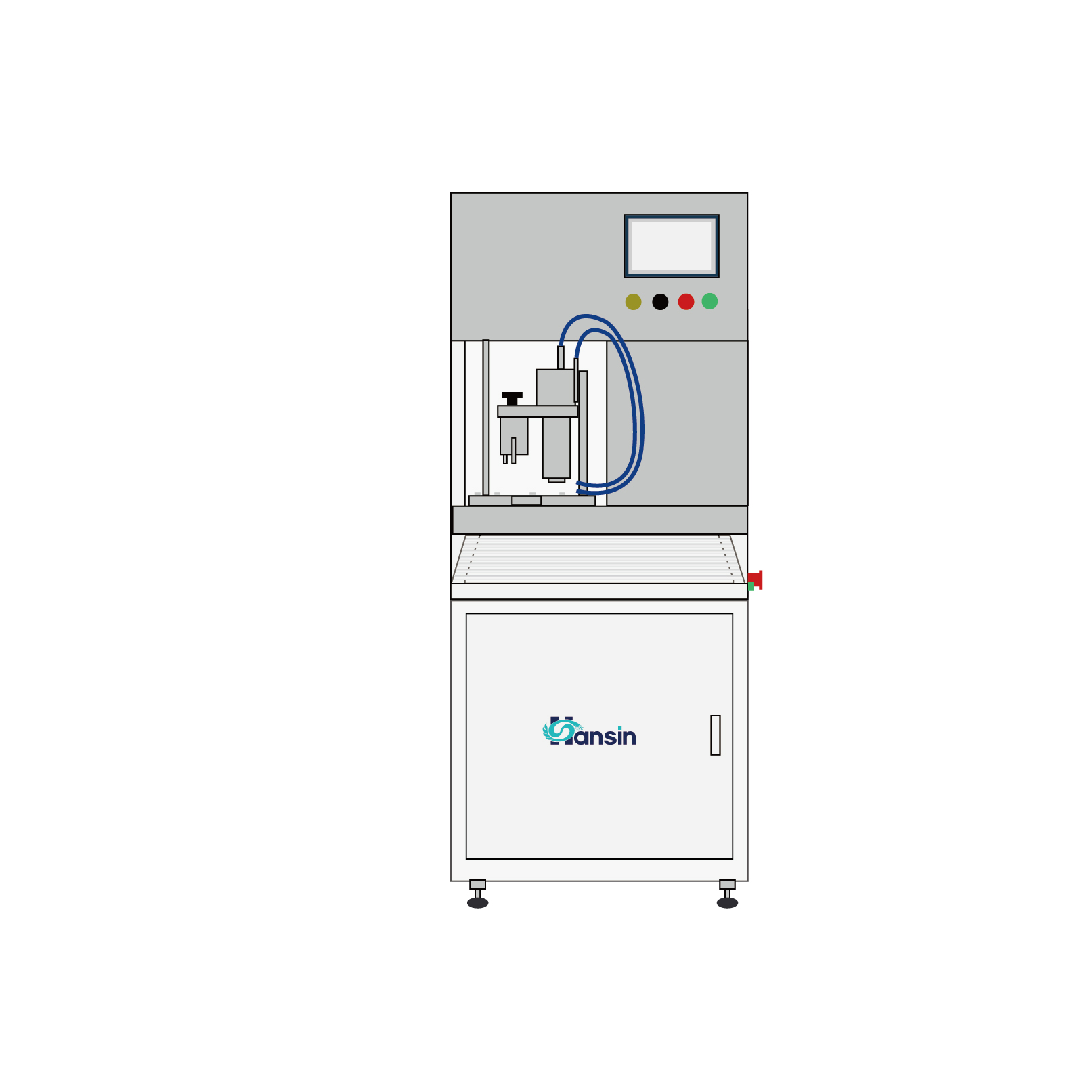

Product images

|

|

|

|

|

|

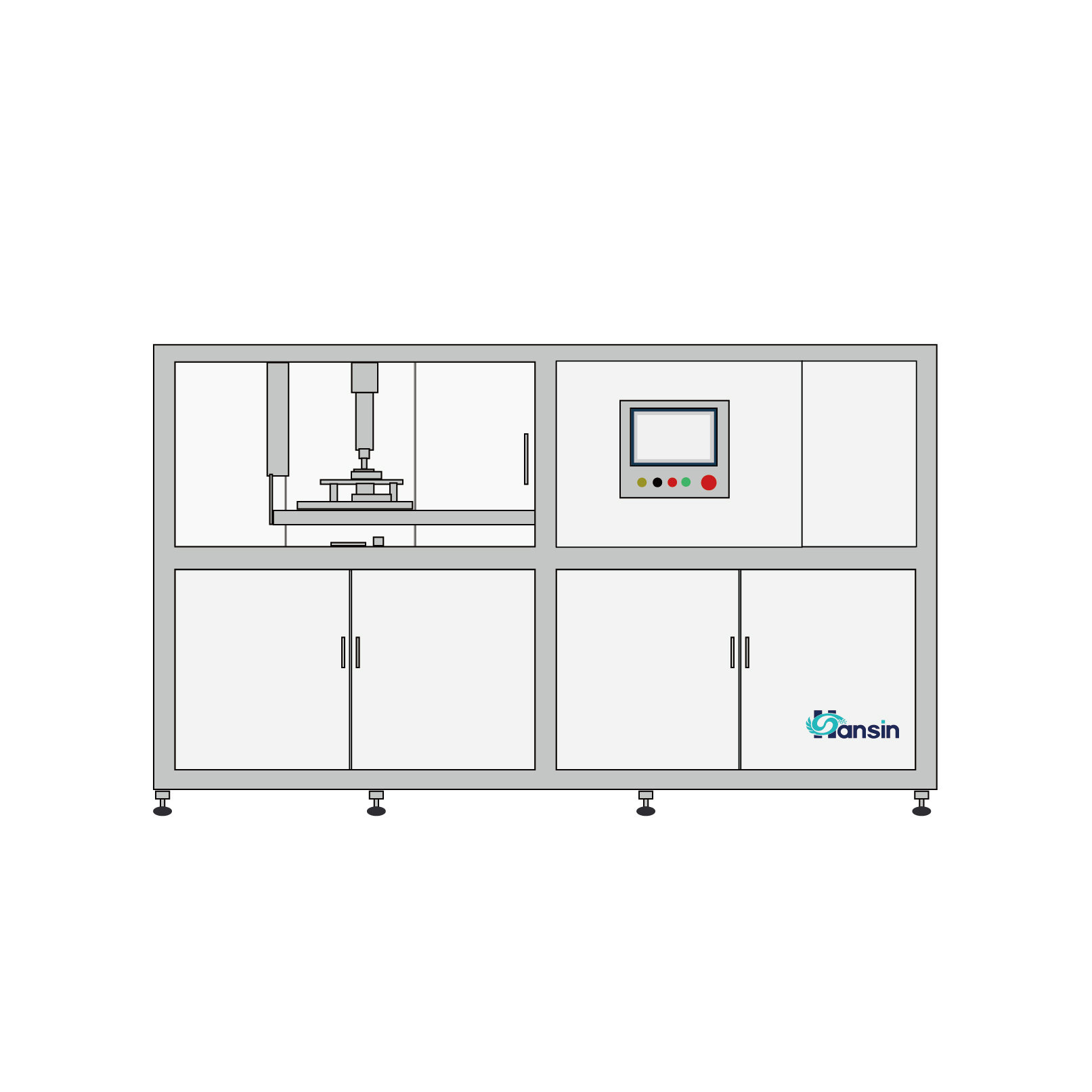

Aseptic

|

Aseptic Filler

|

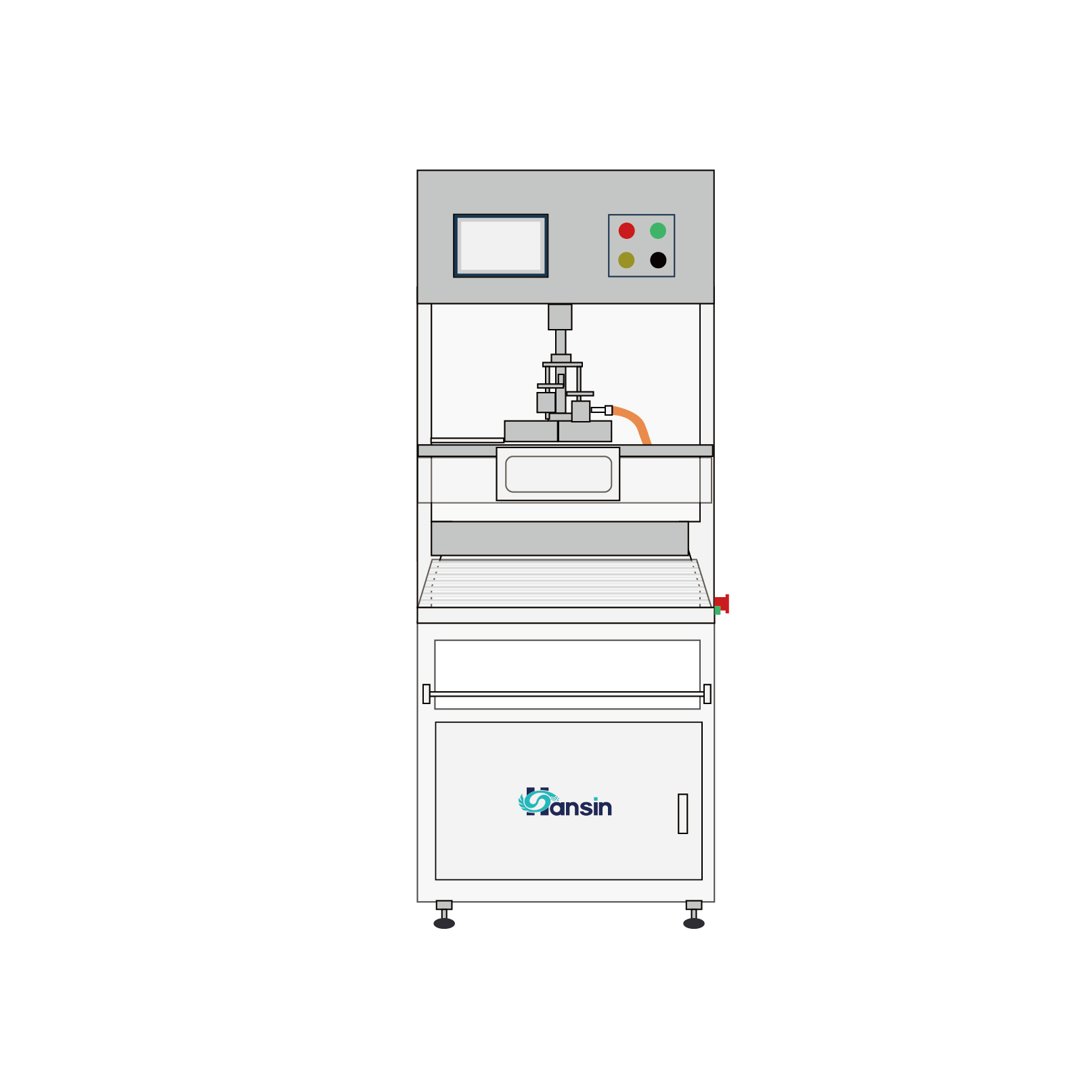

Aseptic Filler

|

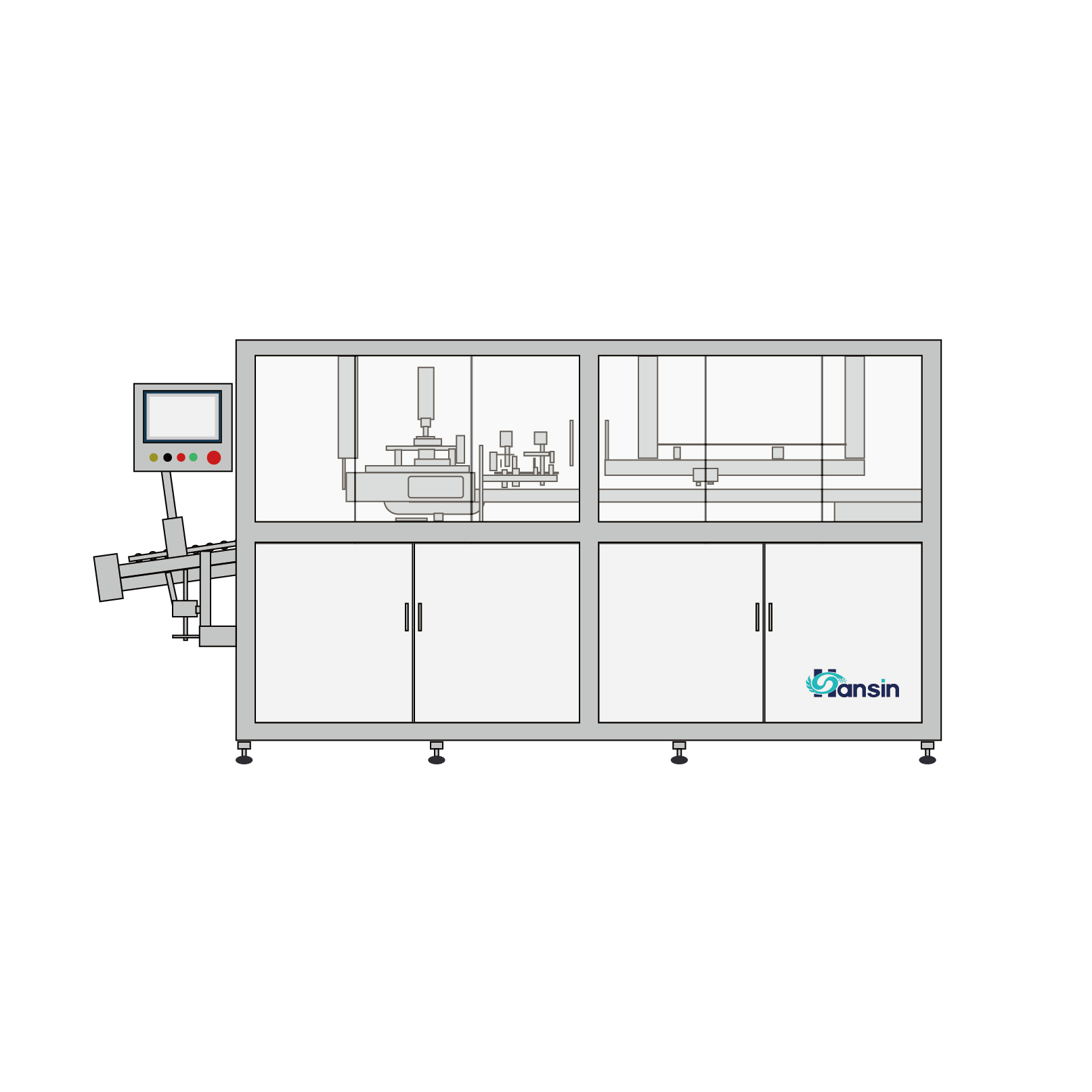

Non-Aseptic Filler

|

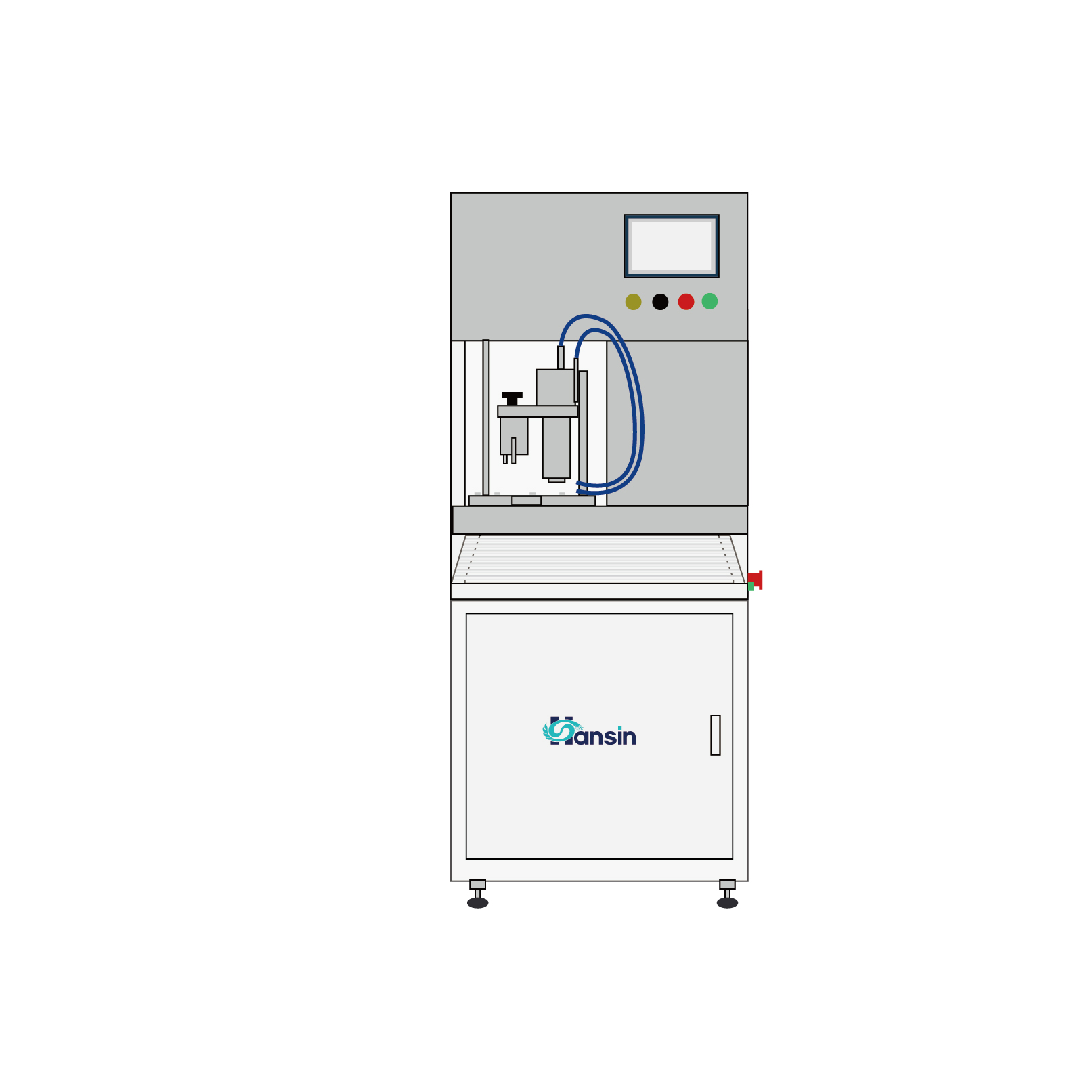

Non-Aseptic Filler

|

|

Model

|

HSAFA-1

|

HSAF-1

|

HSNFA-1

|

HSNF-1

|

|

Operation mode

|

Automatic

|

Semi-Automatic

|

Automatic

|

Semi-Automatic

|

|

Number of heads

|

1

|

1

|

1

|

1

|

|

Filling volume

|

3-25L (1" version only)

|

1-25L (1" version only)

|

3-25L (1" version only)

|

1-25L (1" version only)

|

|

Equipment materials

|

stainless steel SUS304

FDA approved

|

stainless steel SUS304

FDA approved

|

stainless steel SUS304

FDA approved

|

stainless steel SUS304

FDA approved

|

|

Filling meter

|

electromagnetic flow meter

|

electromagnetic flow meter

|

electromagnetic flow meter

|

electromagnetic flow meter

|

|

Operation interface

|

Siemens PLC

|

Siemens PLC

|

Siemens PLC

|

Siemens PLC

|

|

Languages

|

Multi languages

|

Multi languages

|

Multi languages

|

Multi languages

|

|

Cleaning system

|

CIP automatic

|

CIP automatic

|

CIP automatic

|

CIP automatic

|

|

Food steam

|

6~8bar 60kg/h

|

5~8bar 18kg/h

|

/

|

/

|

|

Filling accuracy

|

± 0.5%

|

± 0.5%

|

± 0.5%

|

± 0.5%

|

|

Power

|

220V AC 50HZ 1.5KW

|

220V AC 50HZ 0.5KW

|

220V AC 50HZ 1.5KW

|

220V AC 50HZ 0.5KW

|

|

Compressed air

|

6-8bar 60KG/H

|

6-8bar 16NL/min

|

6~8bar 30NL/min

|

6~8bar 10NL/min

|

|

Nitrogen supply pressure

|

/

|

/

|

Max2.5bar

|

Max2.5bar

|

中文简体

中文简体 英语

英语 西班牙语

西班牙语 俄语

俄语 葡萄牙语

葡萄牙语 法语

法语 德语

德语 意大利语

意大利语