HISTORY OF HANSIN

Hansin company important events record timeline

THE ONLY ABMA MEMBER IN ASIA

Founded in 2006, Hansin Packing has established itself as a specialist in the production of medium and large liquid flexible packaging, focusing on storage and transportation solutions. With over 19 years of experience, we’ve become a trusted name in the industry, driving the development of high-quality packaging and efficient filling systems.

In 2018, we proudly contributed to the formulation of China's national standard for "Composite Bags for Aseptic Packaging of Liquid Foods." Two years later, Hansin made history by becoming the only Asian member of the European Aseptic Bag Manufacturers Association (EU ABMA). Our extensive product range caters to diverse customer needs, offering flexible bag-in-box solutions ranging from 1 liter to 1500 liters, including both aseptic and non-aseptic options, bag in box, 220L aseptic bags, and IBC liners&Form fit liners, stand up pouch, FIBC liners and various kinds of fitments. What sets us apart is our ability to provide a seamless one-stop solution for both filling and packaging. We own advanced filling machines, ensuring that customers receive high-quality packaging and filling services under one roof, saving both time and resources.

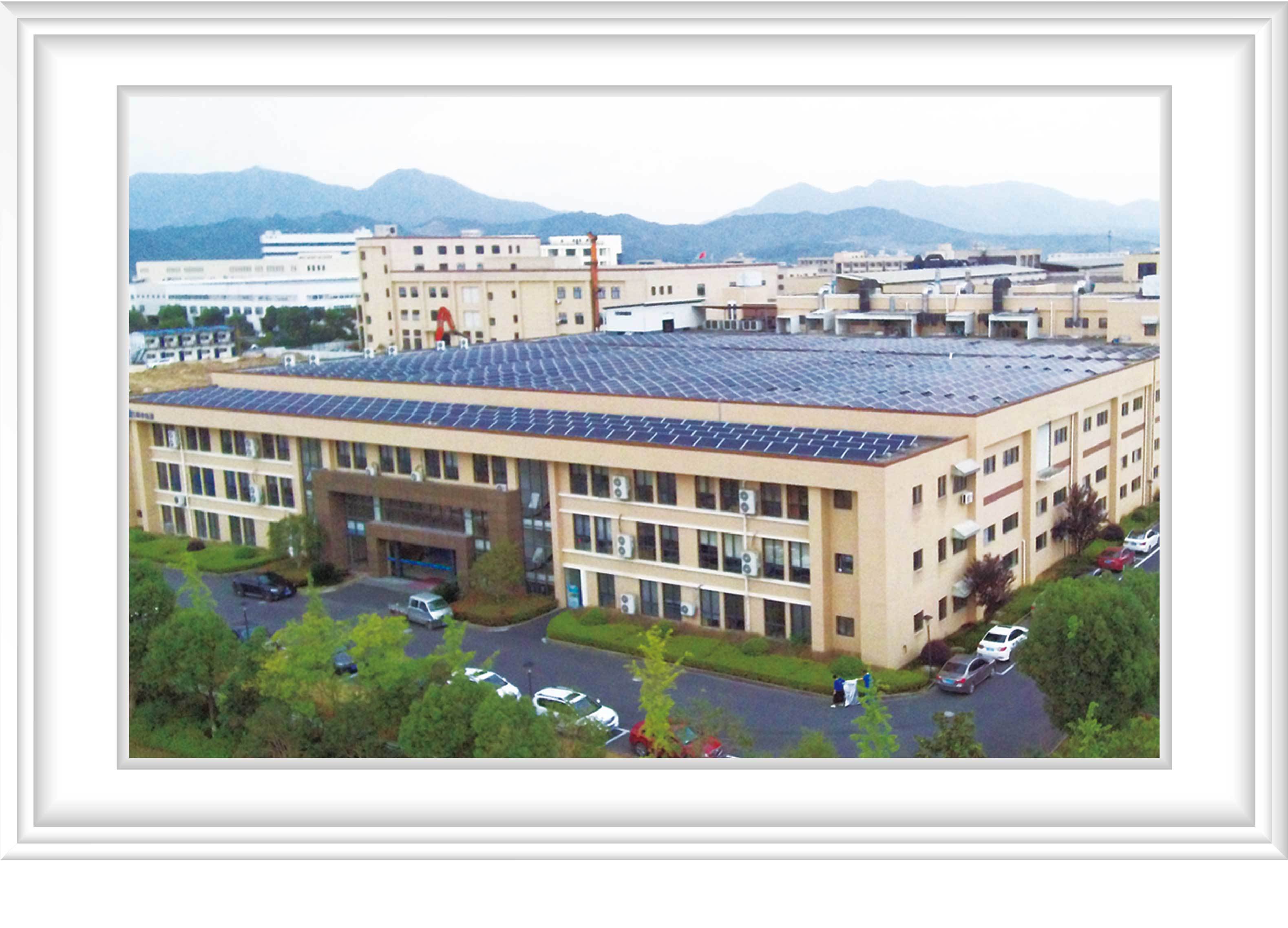

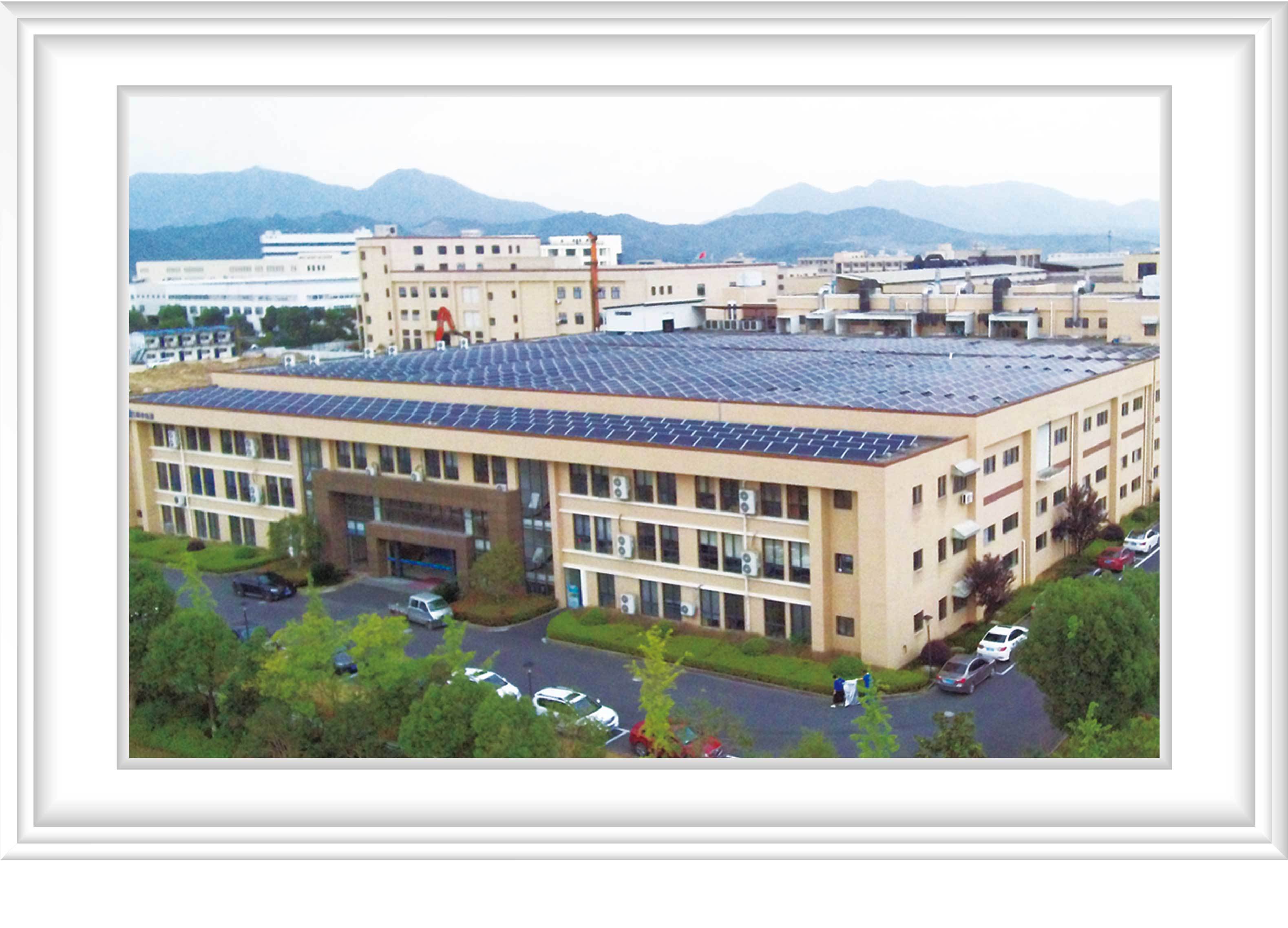

Our facilities are equipped with a GMP 100,000-level clean workshop, where every step of production—from injection molding, film extrusion, and lamination to bag making—is carefully controlled. This ensures that our food-grade packaging meets strict safety standards, guaranteeing the integrity and reliability of every product we produce. With two manufacturing plants in China and branches in Europe, Hansin exports to over 100 countries and regions worldwide. Our composite bags for liquid packaging are widely used in industries such as food, condiments, juice, jam, oil, and paint. The customizable material and barrier properties of our bags help protect products effectively, catering to color sensitivity and the specific requirements of each application. Meantime, Hansin pays great attention to the sustainability.

Hansin Packing is your trusted partner in liquid packaging, offering high-quality products and dedicated service to support and strengthen your brand.

Industrial experience

The company area

Professional equipment

Products export

Well trained staff

Hansin company important events record timeline

What sets us apart is our production experience, flexible film technology and green innovation.

Satisfied with different filling equipment

Stable & Instant & Constant

Support long distance transport & storage

Ensure food safety

Eco-friendly products

Size range from 1L to 220L to 1500L

We have established stable cooperative relationships with many of the top 500 enterprises in the industry.