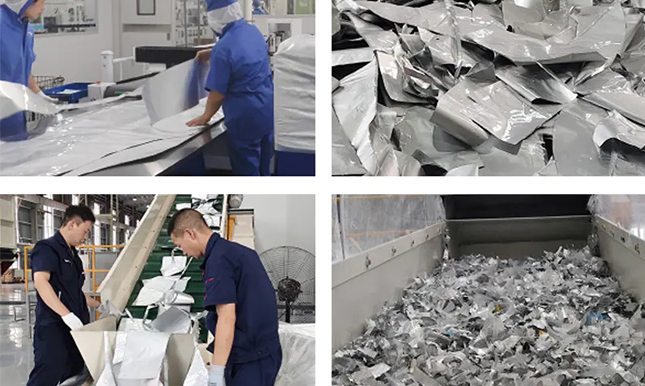

During the production of flexible packaging, trimming materials composed of laminated aluminum foil, nylon, and polyethylene are used as raw materials.

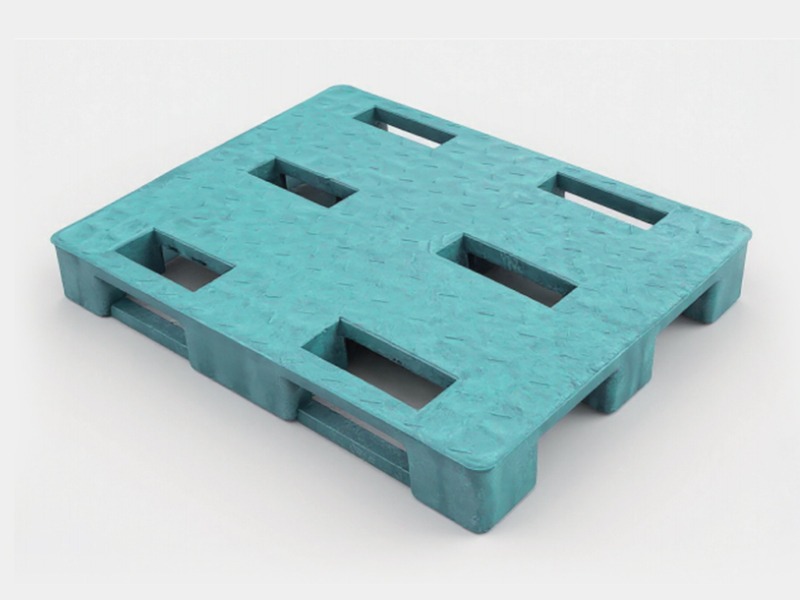

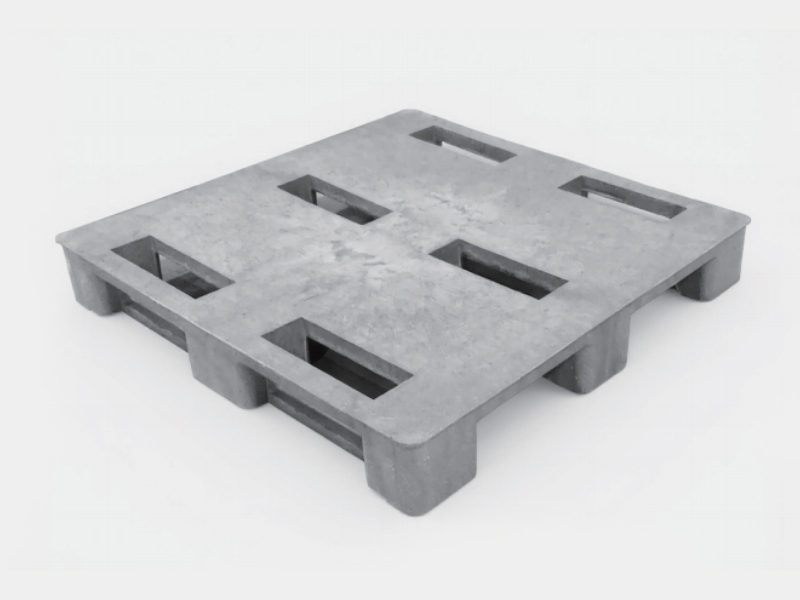

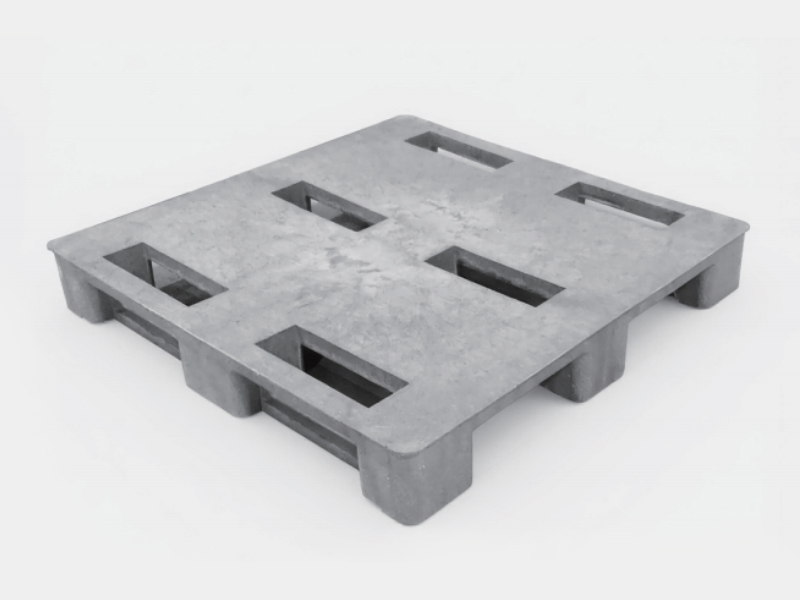

Through a high-temperature, high-pressure compression molding process, the molten material is instantly pressed into the shape of a pallet within a mold,

including intricate structures such as reinforcing ribs, anti-slip patterns, and stacking grooves. The pressure and temperature are precisely controlled to ensure

uniform product density, a compact structure, and stable performance, thereby achieving compliance with food contact requirement standards for the pallet.

Frozen-resistant

Frozen-resistant Payload

Payload Anti-Slip

Anti-Slip Anti-corrosion

Anti-corrosion 100%

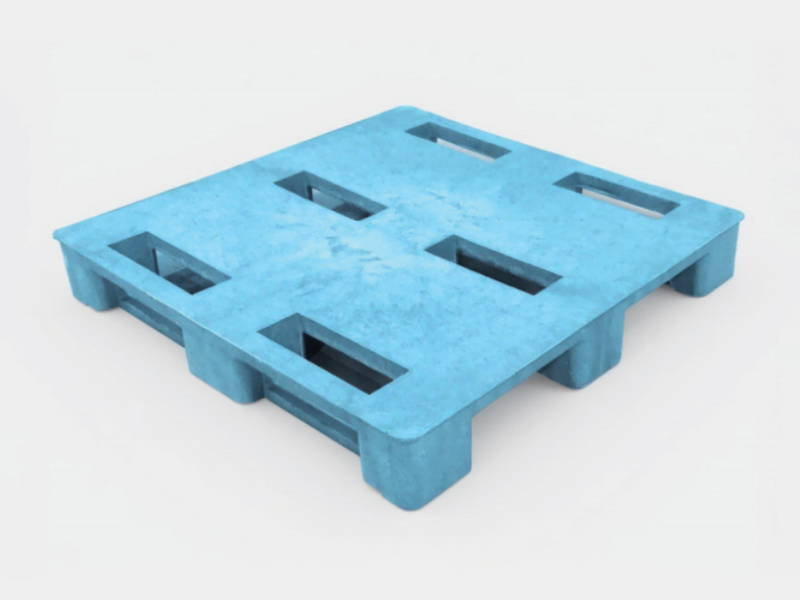

100% Color

Color

中文简体

中文简体 英语

英语 西班牙语

西班牙语 俄语

俄语 葡萄牙语

葡萄牙语 法语

法语 德语

德语 意大利语

意大利语